Review + Interviu – Wooting two HE – Analog control for a digital world

Interviu

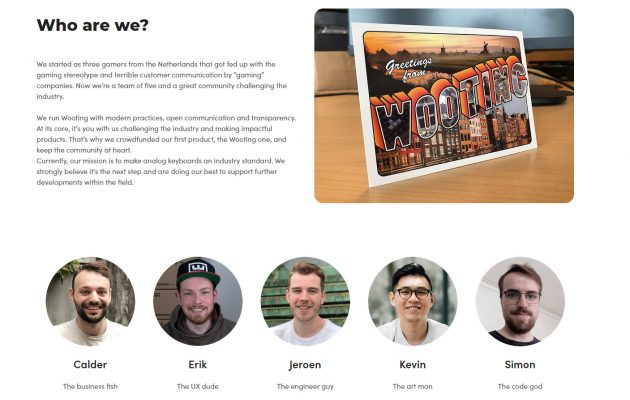

Deoarece Wooting two HE a reusit sa ma impresioneze, am vrut sa aflu mai multe detalii chiar de la cei care o produc, drept urmare le-am trimis o serie de intrebari, iar Calder Limmen – CEO & Co-founder Wooting – ne-a facut onoarea de a ne raspunde personal. Si pentru ca am vrut sa nu alterez in nici un fel mesajul sau, am lasat discutia in forma sa originala, adica in limba engleza.

1 – Hi Calder, thank you for taking the time to answer our questions. First of all, I have to ask, how did you come up with the name Wooting?

The three founders, Jeroen, Erik, and I, know each other from playing various games, namely Guild Wars. At that time, a guild we started named Wooting brought us close together and the name stuck with us as we grew apart with age. The keyboard venture brought us back together and we thought it’d be hilarious to use the word Wooting. Woot was gamer slang during the rise of online PC gaming, it stood for We Own the Other Team. By adding -ing to it, we made it continuous.

2 – What attracted you to HE switches? You initially started with the Flaretech optical switches and then you moved on to the Lekker HE switch- what are the main advantages this switch brings?

We struggled to get the Flaretech optical switches to perform to a level that I imagined when we started. The range was limited and the components sensitive to minor differences. This caused a headache during development, production, and limited our capabilities for features. We had thoroughly tested and determined where improvements could be made, but it slowly became clear that we saturated the technology and interest of the partnering switch manufacturer.

This got me to research other methods. I was inspired by a researcher on human-computer interaction, named Sunjun Kim, who used a hacked together Hall Effect switch to conduct a study requiring analog data. By coincidence, not long after, there was a small movement in the industry for hall effect switches. It was short lived, experimental, and focused on digital input, but it gave me the opportunity to hook our teeth into it and get a project running.

Thanks to the contactless design and the great reliability of both the Hall Effect sensor and magnets, Hall Effect switches are the most durable and robust switches you’d be able to make. This is also why the military uses it for various equipment.

With the Lekker switches we were able to get full switch motion analog input while dealing with less sensitive components. With our experience on a relatively more complex optical solution, it made our development and the production of Lekker switch keyboards a lot easier.

3 – You developed the Lekker switch together with Gateron – how would you describe that cooperation? Were they easy to work with? Did they immediately understand what you needed? Are you happy with the results?

We initially started with a different switch manufacturer named Huano. We were at the time not aware that Gateron was developing a magnet switch in parallel. In both cases, we were not involved in the complete development of the switch, and instead stepped in at a phase that the switch was near completion.

These switch manufacturers don’t offer a complete solution, instead they are experts in mass producing an operational switch, in this scenario, one with a magnet embedded to it. Hence the term magnet switch, not hall effect switch. You still need a hall effect sensor, circuit solution, and software to make it all run. We often step in using existing components and bend it towards our application. We did the same with the Flaretech optical switch, it was originally made for digital input, but we modified it to work for analog input.

In Huano’s case the magnet switch was made as an optical switch alternative for gaming cafes. These types of locations have higher durability requirements and Hall effect switches are an effective solution as it’s not sensitive to any particles, debris, or liquids. Furthermore it’s contactless and easy to swap out for repair.

It was literally a regular switch with a magnet stuck to the side of the stem. This was enough for us to create a prototype keyboard using hall effect sensors, but it didn’t result in necessarily a good sounding and feeling keyboard. This is why we took more time with Huano to create improvements to the switch. This came to an end when COVID-19 struck and Huano didn’t wish to proceed with further R&D, regardless of the money.

This is the moment we stepped to Gateron. I had shortly before learned that they already had a magnet switch in development. The problem was that their magnet positioning and switch concept were different, requiring us to overhaul our circuitry, hall sensor type, and modify the keyboard chassis. When it came to the switch itself, we focused on basic elements such as the magnet, spring, material, and colors to customise it to our liking.

The Gateron team are passionate people with a deep understanding of the mechanical keyboard enthusiast market. We were an ideal candidate for their magnet switches, as we are able to utilise it to its fullest extent and bring it to a broader market. When the cooperation kicked off fast, Gateron was fast to respond and delivered on what we needed. Besides, the Lekker switches feel amazing.

4 – Do you think there is room for an exponential growth in this market segment? Customs keyboards are becoming more and more interesting for users, but HE is still pretty niche – do you think other brands might take your example and use this kind of switches in the future?

The major disadvantage of Hall Effect or optical switches is that you’re locked into a technology with limited switch options. This is no different for our Lekker Hall Effect switches and inevitable if we want to offer analog input. Furthermore, if you opt for analog input, it is more sensitive to mechanical tolerances and build quality, which can limit your build options. These elements make Hall Effect switches less attractive to the custom keyboard market.

This doesn’t mean it’s limited in its potential. The great part about the hall sensors is that it’s indifferent about the switch, it only needs a magnet to work. There is no proprietary technology or design to get started, as both have existed for decades. It’s entirely conceivable to have alternative brand magnet switches to be compatible with our Hall Effect keyboards, and Lekker switches to be compatible with other brand Hall Effect keyboards. As long as they all adhere to similar magnet positioning, similar to how every manufacturer followed the original Cherrymx switch construction and pin location.

Whether other brands will take a liking to Hall Effect switches is entirely dependent on the cost and availability. At this time magnet switches can be produced at reasonable prices, there’ve been some budget variations, but requiring hall sensors per key makes the total far more costly. In addition, going cheap on the hall sensors greatly impacts the accuracy and latency.

I would say for the Hall Effect switches to become more popular, we’d need to see more pre-built solutions offered by keyboard manufacturers and a good reason for consumers to choose a Hall Effect keyboard over a regular keyboard.

The first, so that it’s easier for non-technical/technology focused companies to introduce them to the market. The keyboard space is saturated with marketing focused companies that completely rely on innovation from OEM (keyboard) manufacturers, even when you look at some major brands. It’s honestly quite embarrassing.

The second, so that there’s a reason for manufacturers to offer it and companies to endeavour selling a Hall Effect keyboard. At this time, without analog input and switch alternatives, I see little reason to choose a Hall Effect keyboard over a regular switch keyboard. Even though Hall Effect switches have their own unique feel and experience, there are a plethora of regular switch options that make it far more compelling for the custom market. Then the cost of hall effect keyboards will have a hard time to match that of regular keyboards for the masses.

When you add analog input into the consideration, this might create a tipping point, when there’s a unique feature that is compelling enough. We’ve been at it since 2016 and are still pioneers in its kind. Even though we target a niche market, you can see other major brands have followed our lead into analog input keyboards, such as Cooler Master, Razer, and Steelseries. With the release of our HE series keyboards, I believe we’ve been able to create and perfect a few unique features that will make it extremely compelling for the gaming market to completely convert. It’s never been a question of if to me, always a when.

5 – Do you have any plans to launch a wireless keyboard in the future? How about a different format, other than full and 60% – maybe TKL, or 75%? I am talking, of course, about Hall Effect keyboards.

We made space for a battery in the 60HE case, but we haven’t made any plans to develop a wireless version just yet. There are some challenges when it comes to going wireless such as certification, firmware development, logistics, and battery capacity/hazard. Since we do all our own electronics and firmware/software, this drains a lot of our time going into the first time. With our focus on input latency and squeezing the most out of our keyboards, it’s also not high on our list right now.

We rather spend the time on developing more Hall Effect keyboard layouts. This easily takes 1.5 tot 2 years to complete. We received an increasing demand for anything between 70% to 80%, we’re conceptualising. Perhaps afterwards wireless? Hard to say, who knows next year our team doubled in size and we can work (major) projects in parallel :).

6 – Any plans for QMK/Via support in the future?

QMK doesn’t support analog input nor does it understand how to use our method of scanning keys, so even if we’d allow you to flash the firmware, it’d be a brick. Even if QMK would work, you’d introduce a lot of keyboard latency. QMK was not made for low latency input. Via is an independent party that charges the keyboard makers a license. It was built because only few people are interested in writing code to configure keyboard keys for QMK.

I don’t see the appeal for anybody to flash QMK and use VIA, while you can already do the same and more using our own firmware with the Wootility. We built the firmware from scratch, highly optimised for the hardware. The Wootility, optimising firmware, and new features is also where a lot of our time and effort is spent.

QMK/VIA is great for keyboard companies that don’t specialise in making firmware/software and need a boilerplate to make it run as a keyboard. Or when you want to get rid of bloatware from what are most likely closed branched QMK firmware version with clunky branded pc software.

It’d be more interesting for us to make QMK compatible with our Wootility and add a few QMK specific quirks. Then you’d even be able to configure your QMK keyboard on the web using the Wootility web (wootility.io).

7 – Are you considering launching new Lekker switch models with different specs? Or do you think the current model, plus the different spring option, is enough for Wooting fans and users?

We’d love to introduce more Lekker switch variants, but we’d need sufficient demand and market to start them. We’re not there yet. This is why we opted for spring alternatives first, a relative low-risk method to offer it to customers willing to take the extra mile.

8 – How was the users overall response to the new Wooting two HE? Are people happy with the new keyboard? Did they ask for some specific extra features?

The Wooting two HE was received with great anticipation and we hadn’t disappointed. It was especially exciting to hear from customers that went from our Flaretech optical switch keyboard to now the Hall Effect keyboard. It was and felt as a serious upgrade.

There were a few quirks that we couldn’t test in our own environments and needed some optimization. Such as our key calibration system. Hall effect sensors can be affected by other (electro) magnetic forces in its environment. The sensors are extremely directional (vertical) and overly sensitive to external influences, but since we allow you to set an actuation point of 0.1mm, we need to be very accurate and compensate for influences from your unique environment. Whenever you plug in the keyboard, all the keys will read and calibrate the sensor. With the many new environments, it brought up a few (unique) scenarios we hadn’t thought of to deal with in our software. Making it possible for keys to exceed our 0.1mm threshold in its resting state. This was great for us, as it allowed us to optimize the code. It was of course easily resolved with a firmware update.

Then there was feedback on one key new feature, Rapid trigger.

1. Rapid trigger to be enabled/disabled per key

2. Rapid trigger to only be active anywhere after the actuation point

We have by now added both features to Rapid Trigger and are still closely listening to feedback on features. One long lasting one that we still need to address is extensive Macro support :o). You can already do a great deal with our unique feature Dynamic Key Stroke (DKS), but it’s not entirely the same. We generally recommend using AHK for anything beyond DKS… until we are ready with our own answer to macros.

9 –What’s the general feeling you have after these last 2 years? How do you see the future?

Ever since we launched the Wooting two Lekker Edition (LE), a precursor to the Wooting two HE and project that funded the Lekker switch development, I felt that Wooting was in a transitory phase. We were slowly discontinuing the Flaretech models, building new manufacturer partnerships, and developing a new technology that’d become the new foundation of our keyboards. It was an insane period where we had to be creative with our resources and trust our strengths to bite through a list of challenges. On top of that COVID-19 didn’t make any of it easier, setting off a chain of other issues, such as the IC shortage, factories temporarily closing, and discontinuing projects.

That said, the beauty is that we’ve always found our way through and came out stronger than before. I feel with the release of the Wooting two HE, and recently Wooting 60HE, we’re now in a favourable position to exponentially grow Wooting.

I’m looking forward to growing the Wooting team, community and pleasantly surprising people with our work. I love this.

10 – Once again, thank you for your time!

Comentarii